Search published articles

Volume 7, Issue 1 (8-2013)

One of the major challenges in tunneling is the excavation in regions with high potential of squeezing and in the case of application of full face boring machines evaluation of the required thrust in these regions is inevitable. The Beheshtabad water conveyance tunnel with 65 km in length is considered for transferring one billion cubic meter of water annually to the central part of Iran. According to geological investigation there is a high potential of squeezing in the 19th section of tunnel. In this article, the thrust evaluation methods are investigated and the required penetration force is calculated. Then the numerical procedure applicable to thrust evaluation in the 19th section is discussed and the results are analyzed. In addition, the required thrust to overcome shield skin frictional resistance using Ramoni's method (2010) is computed and the outputs are compared to numerical ones. As a result of numerical simulation, in order to utilize double shield TBM for the sections of 29030-31600 km and 34900-37490 km, it is required to overcut 3 cm for the favorable geomechanical locations and 10 cm for the unfavorable geomechanical conditions. Decision on the application of full face boring machines in the section of 31600-34900 km could be made providing long term parameters of host rock were determined via performing additional in situ tests in the exploration gallery.

Volume 9, Issue 3 (12-2015)

Unpredicted and excessive tool wear is a major challenge in some tunnel projects. Due to more need for maintenance, abrasivity problems increese time and cost of excavation activity. A new laboratory test machine has been built in Engineering Geological Laboratory of Ferdowsi University of Mashhad, to obtain a proper view about relation between performance parameters of a TBM and the soil abrasion. In this paper the results of abrasion tests carried out on silica samples, as an abundant hard mineral, by the machin, are presented. Hence 36 tests have been performed on coarse silica sand samples, with various amount of deadweight and rotation speed at different times. The results prove direct relation between time, surcharge and rotation speed versus tool wear. For example a linear relation between tool wear and surcharge or rotation speed was observed. Besides a logarithmic relation was achieved for time effect

Volume 10, Issue 4 (5-2017)

Evaluation of the excavation-induced ground movements is an important design aspect of supporting system in urban areas. This evaluation process is more critical to the old buildings or sensitive structures which exist in the excavation-affected zone. Frame distortion and crack generation are predictor, of building damage resulted from excavation-induced ground movements, which pose challenges to projects involving deep excavations. Geological and geotechnical conditions of excavation area have significant effects on excavation-induced ground movements and the related damages. In some cases, excavation area may be located in the jointed or weathered rocks. Under such conditions, the geological properties of supported ground become more noticeable due to the discontinuities and anisotropic effects. This paper is aimed to study the performance of excavation walls supported by nails in jointed rocks medium. The performance of nailed wall is investigated based on evaluating the excavation-induced ground movements and damage levels of structures in the excavation-affected zone. For this purpose, a set of calibrated 2D finite element models are developed by taking into account the nail-rock-structure interactions, the anisotropic properties of jointed rock, and the staged construction process using ABAQUS software. The results highlight the effects of different parameters such as joint inclinations, anisotropy of rocks and nail inclinations on deformation parameters of excavation wall supported by nails, and induced damage in the structures adjacent to the excavation area. The results also show the relationship between excavation-induced deformation and the level of damage in the adjacent structure.

Volume 11, Issue 1 (8-2017)

./files/site1/files/3Extended_Abstract.pdfExtended Abstract

(Paper pages 51-72)

Introduction

Value engineering is considered an efficient alternative to improve design and construction process of urban tunneling projects. Application of value engineering techniques can provide investigating all aspects of a project in a team work, creative and short-time manner which contribute to precisely identify a project’s quality improvement issues, construction time and costs.

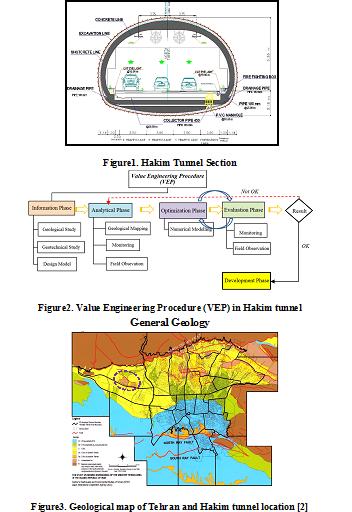

Hakim Expressway one of the capital's main highways in Tehran metropolis with 9 Km in length, starts from the junction of Resalat expressway and Kurdistan expressway after Resalat tunnel and ends in Lashgari expressway. The west extended this highway passing through the area of Chitgar forest park. Due to environmental constraints, the Hakim twin tunnels with cross-section of 186 m2 excavation areas and total length of 3256 m to the NATM/SEM method in this area were excavated (Figure 1).

In preliminary design of Hakim tunnel project, on category of excavation and support system was suggested. During the tunnel’s excavation operation, the behavior and classification of the tunnel were investigated from field observation, instrumentation and monitoring of geological models and subsequently, further excavation process was modified in accordance with value engineering. The aim of using value engineering approach in this project was to reduce the costs without any decrease in quality, employer satisfaction along with minimum risk and as well as improving operational and practical aspects. Ultimately, establishment of the value engineering approach on Hakim tunneling project leads to 10% reduction in construction costs as well as relevant quality with the least challenges (Figure 2).

General Geology

The city of Tehran is founded on Quaternary alluvium, which has been geologically classified by Rieben [1]. The city is located at the foot of the Alborz mountain range, which is basically composed of Eocene pyroclastic deposits (green tuff) and other volcanic rocks. The geology and the morphology of the Tehran region is similar to that for other cities located at the foot of mountains.

Rieben (1966) divided the Tehran coarse-grained alluvia into four categories, identified as A, B, C and D, where A is the oldest and D the youngest (Figure 3).

Hakim tunnel project locates on foothills of northern Tehran, crossing the hills of Chitgar forest park. Results of field surveys indicate that alluvial deposits in tunnel track belong to C (ramps and tunnel portal) and A formations (in most parts of tunnel track).

Geotechnical characterization

Table1 summarizes soil input parameters. Two soil types were considered for the model with 8- meter-height overburden. First layer (No.1) starts from surface with a 1 meter thickness. Second layer (No. 2) has 7 meter thickness.

Table1. Summary of the geotechnical parameters

| Parameter | Unit | Layer No. 1 | Layer No. 1 |

| Internal friction angle (CU) | Deg. | 29 | 33 |

| Cohesion (CU) | Kg/cm2 | 0.15 | 0.45 |

| Density | Kg/cm3 | 18.5 | 20 |

| Poisson ratio of unloading/reloading | Kg/cm2 | 0.2 | 0.2 |

| Secant deformation modulus | Kg/cm2 | 550 | 900 |

| Power of stress level of stiffness | 0.5 | 0.5 | |

| Stiffness unloading | Kg/cm2 | 1650 | 2700 |

Detailed analysis before excavation and continuation of studies led to two excavation and support classes purposed for Hakim tunnel. Both classes of excavation and support due to ground conditions are modeled and analyzed using software Plaxis. For verification, the results of numerical analysis using monitoring and field observations were compared during the tunnel excavation. The results of monitoring compliance with the results of numerical analysis were appropriate.

Implementation and construction costs were calculated for different sections of two excavation and support classes in accordance to contraction documents to evaluate the effect of optimization in design (Figures 6, 7)

.jpg)

Figure4. Excavation sequence in excavation and support class “A”

Results

Results indicate that in both classes maximum costs are related to excavation section while minimum costs are for invert and mucking. In all concrete spray operations there was just a %3.5 increase in costs. Overall savings in excavation and support was about %10 which is significant (Figure 8).

Figure8. Savings percentage comparison in excavation and support classes A and B

Volume 12, Issue 2 (10-2018)

Introduction

The selection of the best subsurface exploration methods corresponding to geotechnical, topographical and economic circumstances of the project is one of the most effective factors in the success of a tunneling project. On the other hand, the development of a decision model and consequently choosing the most suitable alternatives are complex tasks. Therefore, prioritizing and selecting the best subsurface exploration methods, as the main aim of this study, can reduce the economic and social costs associated with the execution of a tunneling project. For this purpose, ten experts from tunneling community have been asked to weigh the chosen criteria of the problem in this research. A methodology utilized in this study is the Analytical Hierarchy Process (AHP) which proved useful in engineering decision-making problems. The other method is TOPSIS, one that has continuously been used in decision making in the recent decades. These two techniques have been combined and utilized in this work to rank the aforementioned exploration methods.

Material and methods

The study area is located about 109 km far from Shahrekord city amid the Zagros mountains. The Sabzkooh tunnel development plan has been under evaluation in the time that this research was being done. The geology of the area majorly encompasses sedimentary rocks which have been outcropped as folds, faults, and fractured and altered zones. However, the variety of the lithological units in the tunnel route is high, and units of limestone and shales also exist over the path.

In the first step, geological and topographic maps were produced for the study area, and general information from the tunnel path was collected and examined. Suitable exploration methods were evaluated, and six main methods were chosen to be considered as the alternatives of the study including (a) discontinuities study, (b) Lugeon tests, (c) RQD, (d) Geo-electric, (e) Gravimetry, and (f) Seismic methods. Moreover, nine criteria ranging from “volume of the available information” and “environmental impact” to “cost” and “accuracy” of the employed methods were taken into account. A pairwise comparison matrix was then developed, and the experts were asked to fill it out. The importance of each criterion was then simply calculated through this matrix. Alternatives pairwise comparison matrices were also filled out and, in this manner, the alternatives could be ranked using the AHP technique. Next, the TOPSIS technique was employed for the same purpose using a rather different process.

Results and discussion

Both AHP and TOPSIS techniques show very close results for ranking of the alternatives in this study. They rank the three Seismic, Geo-electric and Discontinuities studies methods as the best ones for the considered tunneling project. The only difference between these two techniques is how they determine the worst method. The AHP ranks the Lugeon as the last rank among the six methods whereas the TOPSIS determines the RQD as the least reliable method of exploration for the Sabzkooh tunnel project.

Conclusion

The prioritization and the subsequent selection of the most reliable exploration methods for an underground excavation project is a crucial task amid technical decisions. In this research, two major multi-criteria decision-making methods including AHP and TOPSIS were considered and applied for the Sabzkooh tunnel in Iran. The results indicate a high agreement between the two methodologies even though these two approaches decide differently on the least reliable methods to be applied.

Volume 12, Issue 5 (12-2018)

Steel sheet pile walls are being widely used as earth retaining systems. Sometimes loose or soft soil layers are located in various depths in an excavation. This issue causes different effects on ground surface displacements, forces and moments acting on sheet piles and struts during excavation procedure, compared with a status that soil is totally uniform. These differences are not exactly considered in conventional design methods of sheet pile walls. In this paper, a deep excavation using finite element method is analyzed. Excavation’s depth is divided into three different layers. One of three layers is a loose soil layer and its position is modeled in three different situations, top, middle and bottom of the model. Obtained results are compared with results of excavation without the loose layer. The pseudo-static analysis is performed by applying 0.3g horizontal acceleration. The results indicate that when a loose layer is located beneath stiffer layers, bending moments acting on sheet pile wall and shear forces increase about (50~100)% and (15~50)%, respectively. Also, the middle loose layer changes the location of maximum lateral deformation of steel sheet pile wall.

Volume 14, Issue 4 (12-2020)

Introduction

Excavation in urban areas occasionally is accompanied by the improper performance of the support system for even small deformations. In this regard, deformation control design based on force-based approaches provides a more realistic reprehensive of excavation performance. Top-down deep excavation techniques are among the modern excavation stabilization methods in urban areas. In this method, unlike the conventional methods, it is possible to perform the excavation and construction operations simultaneously. The present study aims to investigate excavation stabilization using the main structure through the top-down approach. For this purpose, field and numerical evaluations of the stabilized project were conducted based on the top-down approach in the downtown of Qom city, Iran. This research reports the information obtained through monitoring and modeling using the finite element ABAQUS software, predicting the occurred deformations until the end of excavation operations using the calibrated model, and offering an initial estimation of the required stiffness for the support system with respect to the lateral deformations in four sites proposed, according to the studies of Line A Qom Subway.

Project specifications

Based on the geological studies of Line A Qom Subway Tunnel, the geological layers are classified into four soil classes. Qc-1 consists of gravely sand with fine content of 5 to 20%; Qc-2 is silty and clayey sand with fine content of 35 to 60%; Qf-1 is clayey silt with fine content of 60%; and Qf-2 is a silty clay layer with fine content above 60%. Line A of Qom subway passes the study area of the present study, which is located in Ammar e Yaser Street (Station A6). Based on the geotechnical studies of the project site, the site in the levels near the ground consists of Qc-2 but in the lower elevations, it is composed of Qc-1 and Qf-2.

Salam Trade Complex, located in the downtown of Qom city, has 6 underground stories and 6 above-ground stories. It is limited to the main street in the south and to urban decay in the three other directions. The final excavation depth, length, and width is -21, 36, and 32-52 m, respectively. The project structure consists of a steel moment frame with a retaining wall in the negative elevations and metal deck frame for ceiling construction. In this project, excavation wall deformation was monitored in three important sections (A, B, and C). Due to the vicinity to urban decay, a total station TS02 was used for monitoring these sections. According to the field surveys, the maximum horizontal deformation of the walls in sections A, B, and C is 24.10, 42.16, and 47.21 mm, respectively, which were measured in the 0, -1.5, and 0 m elevations.

Monitoring process and numerical simulation

To calibrate the prepared model, a sensitivity analysis was performed on geotechnical parameters including modulus of elasticity (E), internal friction angle (φ), and cohesion (C) of the layers by simulating 60 numerical models. Based on the sensitivity analysis results, an increase in internal friction angle and elasticity modulus for layer 1 (i.e., φ1 and E1) and elasticity modulus of layer 3 (E3) results in a decrease in lateral deformation. Finally, using the sensitivity analysis results and after several trials and errors, the numerical models for sections B and C were calibrated when reaching the depths of -8 and -11 m, respectively. Using these models, then, it is possible to predict deformations up to the end of the project.

To determine the required stiffness for the excavation support system, regarding the acceptable deformation of the adjacent soil mass, 160 numerical models were built and their results were analyzed. Based on the results of Brason and Zapata (2012), relative stiffens (R) were used to develop a relationship between the maximum lateral deformation of the wall and the required stiffness of the support system. R is a dimensionless parameter that represents the stiffness of a solid support system; the greater this value is, the more flexible the system would be. In this study, caisson pile length, excavation width, and buried depth of the wall were used for determining the R.

R =

(1)

(1)Figure 2 presents the maximum occurred deformation in terms of depth versus the relative stiffness for sites QC and QF.

Figure 2. Maximum deformation in terms of depth versus the relative stiffness for sites QC and QF

Conclusion

- According to the monitory data, the maximum lateral deformation in sections B and C until the end of the project was 42.16 and 47.2 mm, respectively. Moreover, the deformation of the other points inside the excavation was 30 mm.

- Considering the occurrence of maximum lateral deformations in the higher elevations in the monitored sections, it is inferred that excavation support at the ground level plays a key role in this approach. Hence, the lack of completing the structural frames and slabs for facilitating the excavation operation can lead to an increase in deformation levels.

- Based on the prepared graphs, the top-down approach in sites QC-2 and QF-2, compared to sites QF-1 and QC-1, provides a more desirable performance for deformation control.

Volume 17, Issue 3 (12-2023)

Volume 19, Issue 6 (12-2025)

The developed framework offers substantial practical advantages including cost reduction through minimized laboratory testing, rapid prediction capabilities for quality control, and enhanced risk assessment through uncertainty quantification. The integration of petrographic analysis with machine learning provides engineers and practitioners with a scientifically robust and economically viable approach to rock strength assessment, supporting more reliable engineering design and reducing the risk of costly project failures.

| Page 1 from 1 |

© 2025 CC BY-NC 4.0 | Journal of Engineering Geology

Designed & Developed by : Yektaweb